ADVANTAGES OF MOBILE SODA BLASTING

Often, the coating of a material is cleaned before undergoing the procedure of blasting especially for tasks where it is covererd with taints like carbon, grease, and salt. This is essential to prevent future coating failure because such taints can seep through the coating into the material’s substrate. With soda blasting cleaning, the risk of damaging the base layer is mitigated as no pre-cleaning is involved.

With soda blasting cleaning, you get to witness the cleaning wonders of its main component, the sodium bicarbonate. The crumbly and soft features of this compound makes a different cutting action with minimal or no effect on most material surfaces. For instance, thick coatings on a glass can be cleamed without making a chip.

In most less risky application of soda blasting, the leftover with soda blast media can be rinsed into sanitary sewers, which will transfer it to a water treatment facility. This is immensely reduce the clean up time. Sodium carbonate has been known to be important to waste water treatment systems. Soda blast is an affordable alternative to chemical neutralization for water treatment.

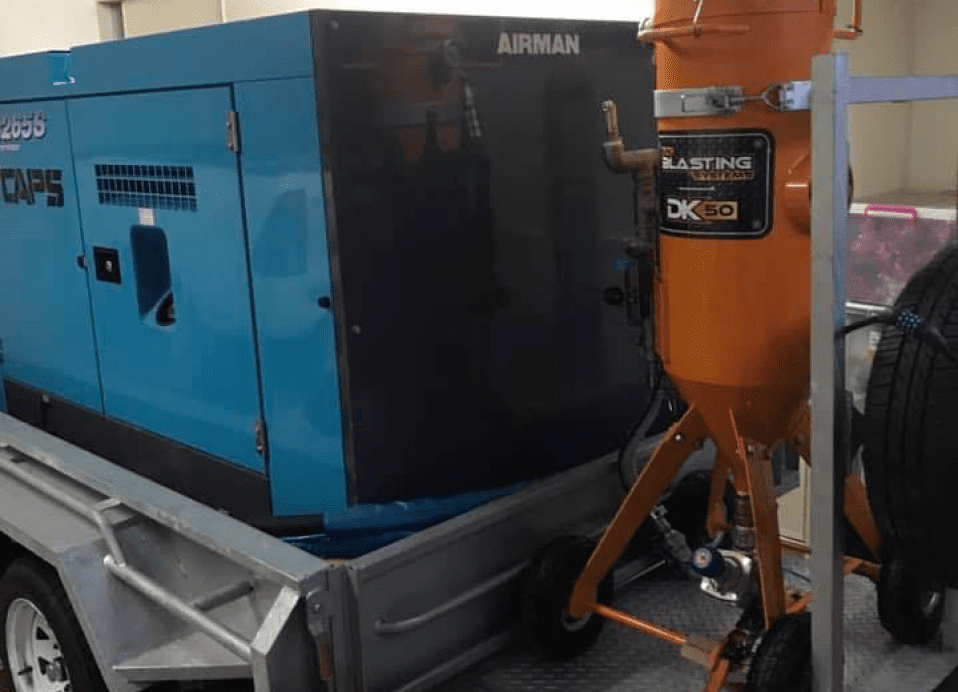

Machinery Soda Blasting

Machinery Soda Blasting Building Soda Blasting

Building Soda Blasting Automotive Soda Blasting

Automotive Soda Blasting Marine Soda Blasting

Marine Soda Blasting Other Soda Blasting

Other Soda Blasting